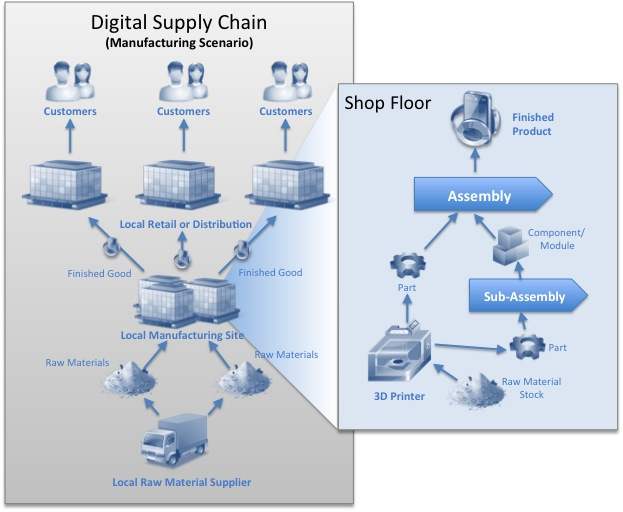

Although separation of product design from manufacturing capabilities is a major advantage of Additive Manufacturing (AM), the impact of AM is not only limited to the design and manufacturing stages. In addition to the freedom of design such as elimination of design constraints, material saving, and free complexity, AM offers other potential benefits to the manufacturing industry as well. One of the most immediate potentials of AM is the possibility of more efficient logistics. This paper aims at describing the characteristics and requirement of a Supply Chain (SC) as well as the changes AM will bring into the current structure of supply chain. Insights are provided on the transformative effects of AM on traditional businesses, and how these changes impact the configuration of a supply chain. The potential for using simulation tools to evaluate AM supply chain have been discussed. Further, two examples of Agent Based Simulation (ABS) and System Dynamics (SD) have been provided to show the application of simulation models. The ABS results show the possibility of lead time reduction in AM based supply chain. In addition, the SD model illustrates the potential for less ‘pipeline’ effect in AM compared to traditional supply chain.

Read more about this study:

Impact of Additive Manufacturing Adoption on Future of Supply Chains