Software-Hardware Recycling and Repair Dataset Infrastructure (SHReDI) for Sustainable Computing

This collaborative project, between researchers from Oregon State University and the University of Florida, aims to address the rising issue of electronic waste (e-waste). The project modernizes electronics design and improves e-waste logistics to increase recovery rates of valuable materials, which are frequently lost to landfills or incineration. The project develops innovative low-cost wireless tags and computational models to improve the environmental and economic impacts of e-waste recycling. These wireless tags will equip recyclers with critical information on material composition and optimal recycling methods, while the computational models will support decision-making by quantifying the sustainability and economic viability of e-waste recovery. Furthermore, the project facilitates the tracking of recycled materials back to producers and supports policies for more equitable recycling cost distribution. The project combines advanced integrated circuit design with strategic e-waste management practices to establish a circular economy for electronics.

Human-Robot Collaboration for Disassembly of End-of-Use Products

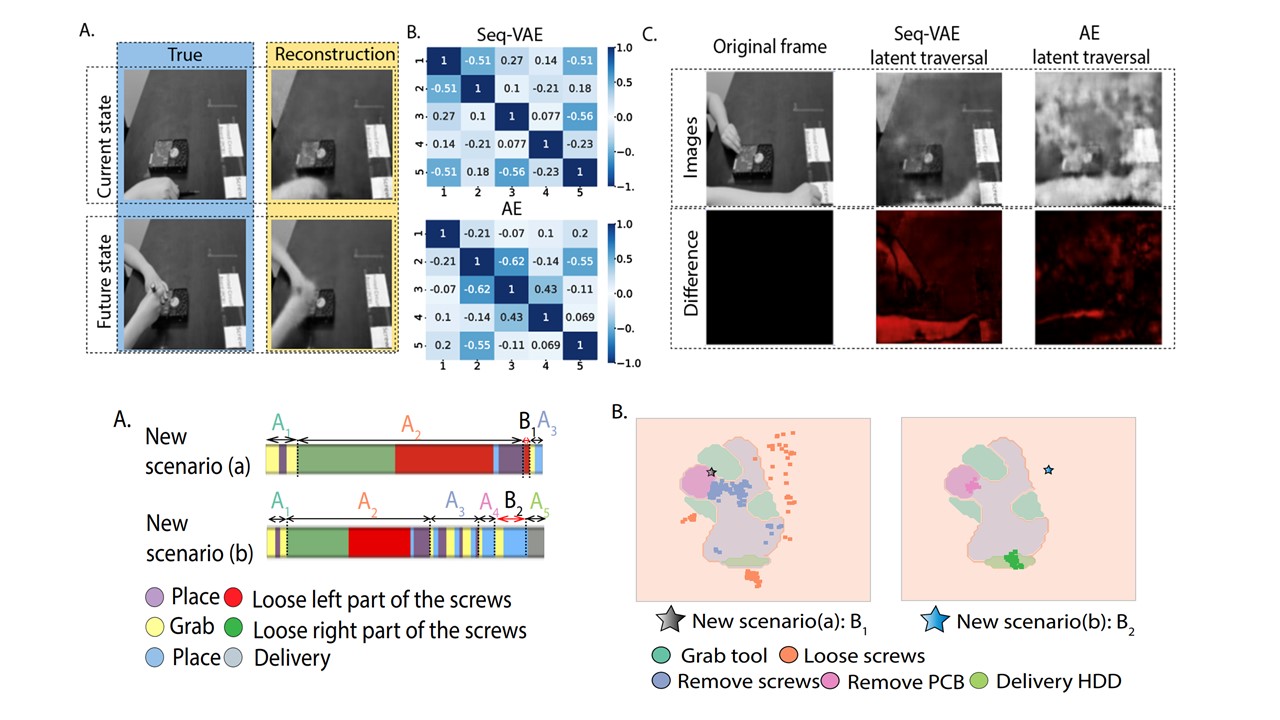

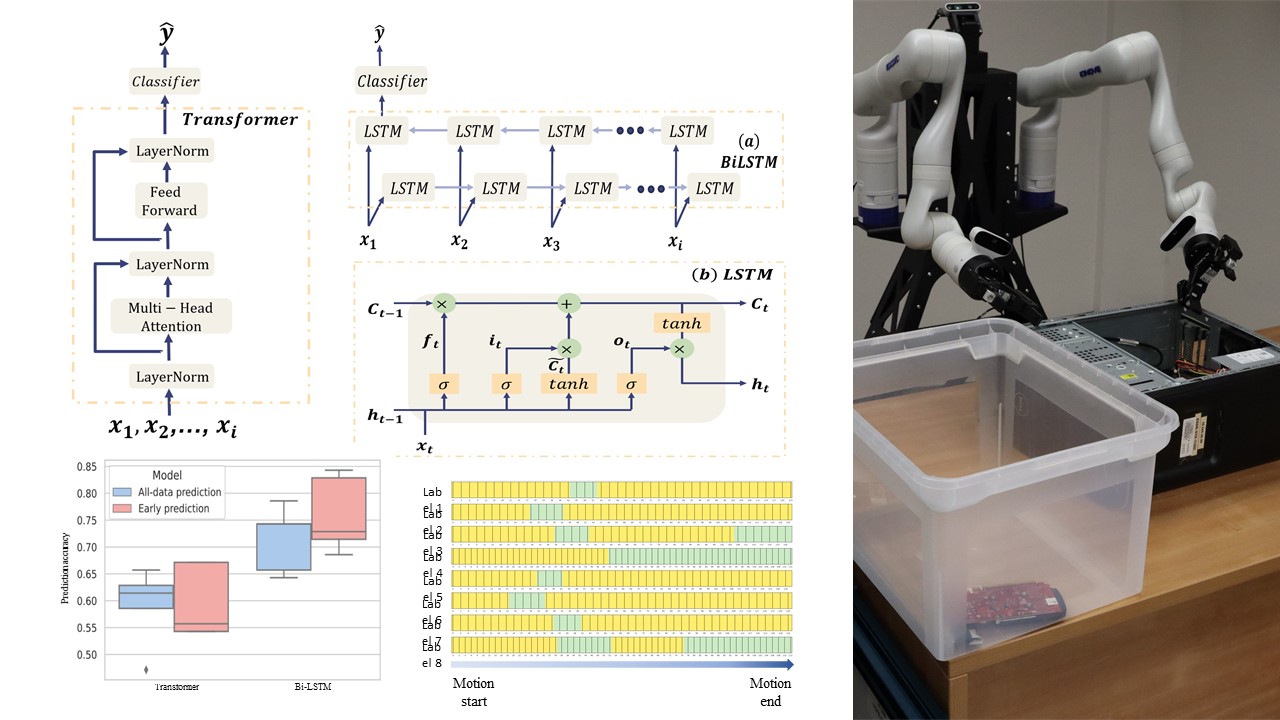

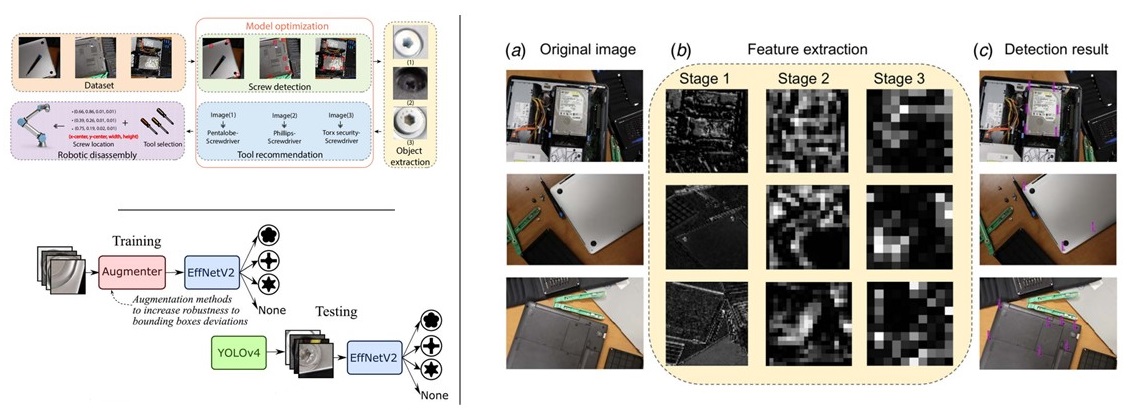

This research project is part of the NSF Future of Work at the Human-Technology Frontier (FW-HTF) initiative and aims to advance the electronics remanufacturing industry by developing human-robot collaboration (HRC) for the disassembly of end-of-use consumer electronics. The project addresses the labor-intensive and hazardous nature of electronics disassembly and improves job satisfaction, and worker safety through robot-assisted disassembly processes. The project is a joint effort between the University at Buffalo (UB) and the University of Florida (UF), to reduce costs, minimize waste, and improve the recovery of valuable materials by advancing robotic disassembly technology. Our research will advance task distribution, cooperation, and interaction between humans and robots. The research covers a wide range of topics including work environment monitoring, collaborative robotics, disassembly planning under uncertainty, human-robot system integration, and the economic consequences of HRC in remanufacturing. We combine approaches from different disciplines such as robotics, sustainable design, human factors, data science, and labor economics. The outcomes of our research provide the foundation for economically viable, human-robot collaborative systems in future remanufacturing operations.